Most important Challenges of Friction Stir Welding are application of high temperature materials Tool material selection Development of Tool Materials Tool design and Complex geometries and dissimilar materials. The tool materials include tool steels superalloys refractory metals carbides and ceramics and superabrasives.

Friction Stir Welding Tools With Different Pin Profiles All Dimensions Download Scientific Diagram

Friction Stir Welding Tools - Functions Designs and Materials Published on November 14 2018 November 14 2018 11 Likes 0 Comments.

. This process is experimental and the keywords may be updated as the learning algorithm improves. The mixing the material flow conditions specifically affect the quality of the weld so the Tool geometry is very important. Friction Stir WeldingProcessing Tool Materials and Selection.

EXPERIMENTAL SETUP AND PROCEDURES Materials The material used in this study 6061 Al alloy was received from Misr Aluminum Company. Process in such a way that the design of new tools for new materials could be accelerated. Metal Cutting Theory and Friction Stir Welding Tool Design Author.

The system collects tool temperature Z-axis load and data wirelessly for fine-tuning the FSW process while analog outputs enables integration with MAZATROL Smooth controls for temperature or force-based. This article discusses materials for friction stir welding FSW pin tools various tool geometries that have been used designs for specific applications predicting and measuring tool performance and other considerations in FSW pin tool design. Since there is no bulk melting of the.

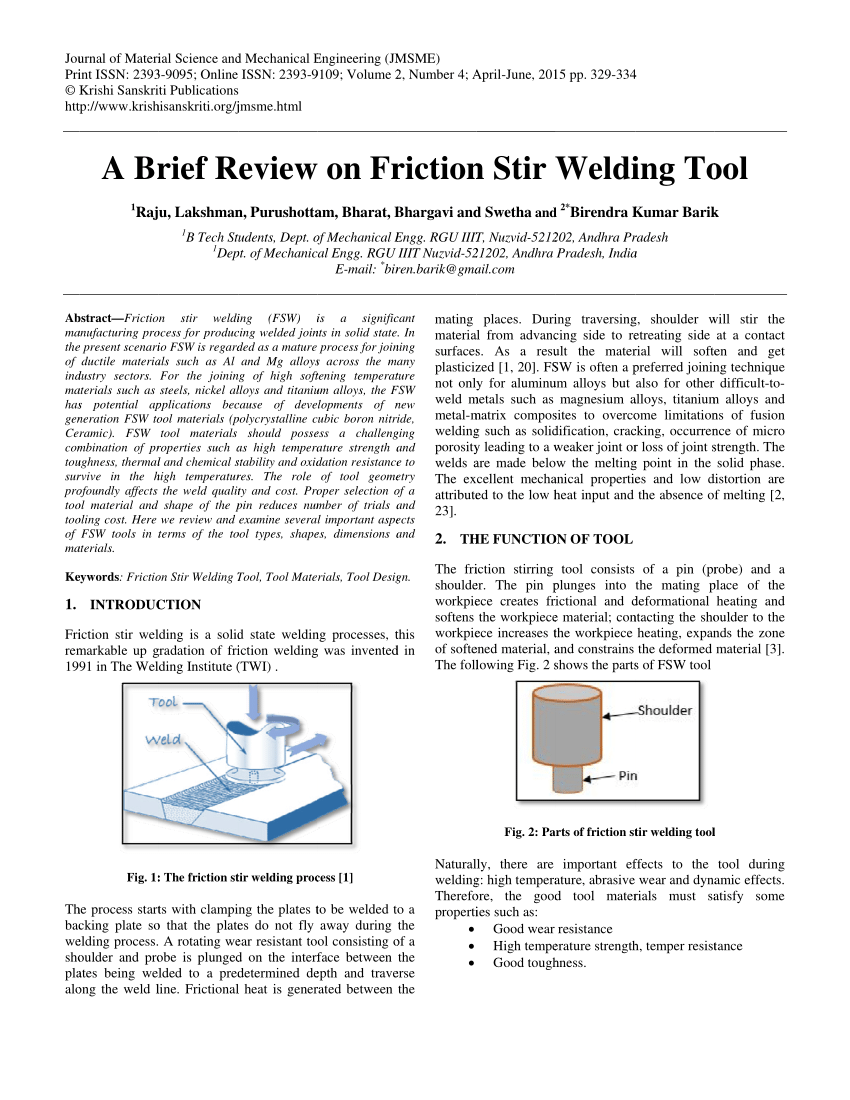

Friction stir processing FSP is a new solid state processing technique that can locally eliminate casting defects and refine microstructures thereby improving strength and ductility increasing. Contacting the shoulder to the workpiece increases the workpiece heating expands the zone of softened material and constrains the deformed material. So there are two important aspects of friction stir welding tool design.

Drawing on experience from manufacturing Friction Stir Welding tools since the invention of the process in 1991 we manufacture tooling for a range of industries and provide advice and support. Friction Stir Tooling Tool Materials And Designs. Tool design and selection of process variables are critical issues in the usage of FSW process.

The Friction stir welding is a dynamically developing version of pressure welding processes by which High-quality welds can be created. Along the way several successful new tooling designs were developed for current issues at the. The tool typically consists of a rotating round shoulder and a threaded cylindrical pin that heats the workpiece mostly by friction and moves the softened alloy around it to form the joint.

The friction stirring tool consists of a pin or probe and shoulder. Friction Stir Processing of Materials. Friction stir welding FSW is a process for joining materials in the solid phase using a non-consumable tool.

Friction Stir Processing of Materials. Production engineering Delhi Technological University India. Friction stir welding FSW was invented by TWI in 1991 1 and substantial development has been conducted subsequently.

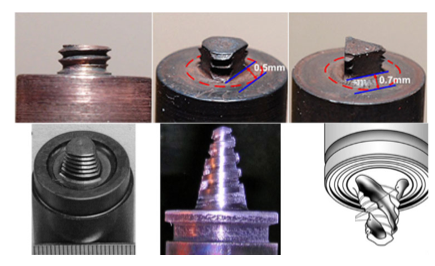

Is a screw threaded taper pin with a concave shoulder. Tools Design and Microstructural Characterization. The shape of the friction stir tool.

A friction stir welding FSW 1 5 tool is obviously a critical component to the success of the process. The FSW Intelligent Tool Holder is an all-in-one tool holder and telemetry system that offers the ability to use Friction Stir Welding FSW on Mazak machine tool platforms. Full PDF Package Download Full.

Commonly used tool materials Tool steel Materials such as aluminium or magnesium alloys and aluminium matrix composites AMCs are commonly welded using steel tools817 Steel tools have also been used for the joining of dissimilar materials in both lap and butt configurations1825 Lee et al18 welded AlMg alloy with low carbon steel in lap joint. Friction stir tooling tool materials and designs Mention a contemporary and vibrant design. General material fl ow in FSW process was studied using the.

Material Flow Friction Stir Welding Tool Material Tool Shoulder Faying Surface These keywords were added by machine and not by the authors. Tool Design The tool must be designed to generate. Up to 10 cash back The friction stir welding FSW is done of AA2024 plates in butt joint configuration using modified vertical milling machines setup.

BT-FSW is characterized by a fully penetrated pin and double-sided shoulder that. 1 to visualize the cross section of the various tool pin profiles along with their isometric views. Materials welded experience plastic deformation at elevated temperatures creating a weld zone consisting of a wrought microstructure instead of the solidification microstructure produced by fusion welding methods 1 2 3.

Joints of 6061 tubes after friction stir welding. Tool material and geometry 2. Friction stir welding FSW is a widely used solid state joining process for soft materials such as aluminium alloys because it avoids many of the common problems of fusion welding.

Screw threaded taper pin. With a wide range of machinery we can fully meet your. Making a choice in selection of friction stir weldingprocessing FSWP tool material has become an important task which determines the quality of the weld produced.

Tools Design and Microstructural Characterization. This nail art injects an exciting character in you. Commercial feasibility of the FSW process for harder alloys such as steels and titanium alloys awaits the development of cost effective and durable tools which lead to structurally sound.

A 3D model is shown in Fig. The tool pin profiles are conical pedal cylindrical with thread triangular square and. This work aims to optimize the performance evaluation characteristics such as the temperature at the weld center of the lap joint Tw the tensile shear load TSL and the hardness using an experimental design experiment for bobbin tool friction stir welding BT-FSW of AA1050 lap joints.

Tables 1 and 2 show the chemical composition mechanical and physical properties of 6061 Al alloy. With The sunshine pinkish and white shades combined with the seemingly washed on peach colored petals demonstrates as When the sun has picked to glow on you and only you. Contact of the pin with the workpiece creates frictional and deformational heating and softens the workpiece material.

It allows metals including aluminium 2-12 lead 13 magnesium 14 steel 15 titanium 16 zinc copper 17 and metal.

Tools For Friction Stir Welding

New Tool For Joining Ti 6al 4v By Friction Stir Welding Twi

A B Schematics Of The Tool Design And Fsw Of Dissimilar Materials Download Scientific Diagram

Advances In Tooling Materials For Friction Stir Welding Innoval

Friction Stir Spot Welding Tool Design Showing Geometric Parameters Download Scientific Diagram

0 comments

Post a Comment